| |

|

|

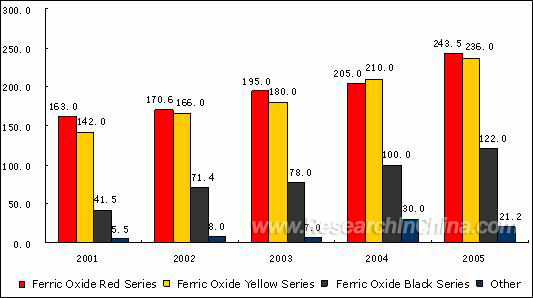

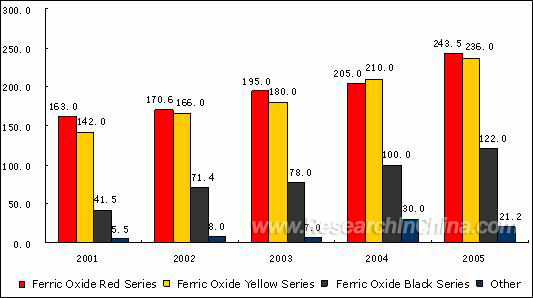

In 2005, the production capacity of ferric oxide in China exceeded 700 kiloton, the total output to 622.7 kiloton and export volume to 329.5 kiloton. Ferric oxide products are mainly exported to North America, Europe and Southeast Asian.

Output of China's various Ferric Oxide,2001-2005 (unit: kiloton)

Source: China Association of Ferric Oxide Industry

The producers of ferric oxide in China mainly locates in southeast coastal area, from northern China to Yangtze Delta and southern China, 23,000 ton of output in Shandong and 18,500 ton in Hebei, 183,000 ton in Jiangsu, 233,000 ton in Zhejiang and 100,000 ton in Shanghai, 11,000 ton in Fujian and 8,000 ton in Guangdong. The total production capacity of ferric oxide in this coastal area reached 557,500 ton, accounted for 79.64 percent of the national production capacity. If all production equipment is put into production, it is no doubt that the coastal area will become an eye-catching production base of ferric oxide.

The scale expansion of China's ferric oxide industry has not only drew wide attention from relevant industries such as steel industry, smelting industry, titanium industry and sulfuric acid industry, but also attracted oversea manufacturers and sales companies. Some foreign ferric oxide manufacturers and sellers are optimistic of Chinese market, like Bayer, Rockwood and Elementis. They have already established sole proprietorshipenterprises or joint ventures in coastal area, like Shanghai, Fuyang(in Zhejiang) ,Changshu & Taicang(in Jiangsu), and Shenzhen. Nowadays, Jiangsu, Zhejiang and Shanghai and Guangdong become production bases for foreign ferric oxide manufacturers. Most of these foreign manufacturers mainly purchase primary products of ferric oxide, and then process them, whose annual production capacity exceeds 120,000 ton.

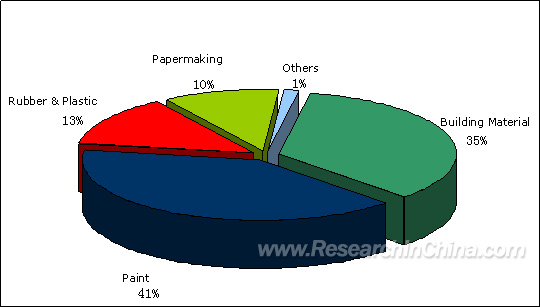

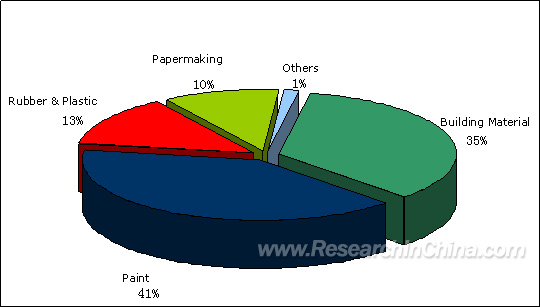

Ferric oxide products are mainly applied in the field of paint, also applied in magnetismmaterials. Ferric oxide is widely applied in paint industry, among inorganic color paints, the output and demand of ferric oxide is the largest. It is applied in various precast concrete units in construction industry and used as paints or colorants for construction products such as color floor tile, metope decoration, terrazzo floor and color tile. In addition, it is also applied in the pigmentation of various paints and protective substances (including water interior & exterior paint, powder paint) and oil paint (including various priming paints and finish paint). Ferric oxide paint can be also applied in rubber, plastic, ceramics, cosmetic, medical, paper and leather industry.

Main Applications of China's Ferric Oxide Products in 2005

Source: China Association of Ferric Oxide Industry

In 2006, the supply of China's ferric oxide will be balanced and ample, not excluding shortage or overstock in some areas or within certain manufacturers at a particular period.

Influenced by the history and social background, China has four major advantages to develop ferric oxide industry: skilled and low-cost labor force, rich raw materials, professional technical personnel and large market at home and abroad.

Ferric oxide industry belongs to a labor-intensive industry with resource and energy consumption. Along with the requirements of China environmental protection policies and development trend, higher requirements are put forward to protect the environment during ferric oxide production. Chinese government attaches great importance to production and management of ferric oxide industry, therefore a reasonable, moderate and feasible control on total demand of ferric oxide has been worked out. China has already released relevant policies to restrict these manufactures in immature production conditions with annual output below 5,000 ton, which not only waste resource but pollute environment, so as to protect exporting manufactures, to ensure reasonably utilize resource and to reduce pollution influences on social environment.

It should also be noted that problems co-exist with the rapid development of China's ferric oxide industry. On one hand, low threshold to ferric oxide industry caused mass production and long-term repeated construction, regardless of market demand; on the other hand, the primary products of China's ferric oxide accounts for a big market share, which means the quality of ferric oxide products is still at middle-low level in international market; moreover, the value added to products is low. Restricted by the requirements of energy, resources and environment, the production of ferric oxide is under higher pressure. Export is also hindered by Euramerican economic fluctuation and trade bulwark.

In general, China's ferric oxide industry has a good prospect. The construction of rural-urban infrastructure will stimulate the demand of ferric oxide as construction paint. Particularly, the start-up of Beijing 2008 Olympics project and Shanghai 2010 World Expo project will drive the development of ferric oxide industry. What's more, the demand of China's ferric oxide products in oversea market is also large. As long as China's ferric oxide manufacturers seize this opportunity, speed up saving energy and reducing energy consumption, develop new products and improve the value added to products, more market shares can be occupied.

|

|

|

|

|

If this report could not still meet your requirement, or

you have any comments or suggestions on it, please leave a

message to us.

|

2005-2007 www.researchinchina.com All Rights Reserved

| |

|

|

| |

|

In 2005, the production capacity of ferric oxide in China exceeded 700 kiloton, the total output to 622.7 kiloton and export volume to 329.5 kiloton. Ferric oxide products are mainly exported to North America, Europe and Southeast Asian.

Output of China's various Ferric Oxide,2001-2005 (unit: kiloton)

Source: China Association of Ferric Oxide Industry

The producers of ferric oxide in China mainly locates in southeast coastal area, from northern China to Yangtze Delta and southern China, 23,000 ton of output in Shandong and 18,500 ton in Hebei, 183,000 ton in Jiangsu, 233,000 ton in Zhejiang and 100,000 ton in Shanghai, 11,000 ton in Fujian and 8,000 ton in Guangdong. The total production capacity of ferric oxide in this coastal area reached 557,500 ton, accounted for 79.64 percent of the national production capacity. If all production equipment is put into production, it is no doubt that the coastal area will become an eye-catching production base of ferric oxide.

The scale expansion of China's ferric oxide industry has not only drew wide attention from relevant industries such as steel industry, smelting industry, titanium industry and sulfuric acid industry, but also attracted oversea manufacturers and sales companies. Some foreign ferric oxide manufacturers and sellers are optimistic of Chinese market, like Bayer, Rockwood and Elementis. They have already established sole proprietorshipenterprises or joint ventures in coastal area, like Shanghai, Fuyang(in Zhejiang) ,Changshu & Taicang(in Jiangsu), and Shenzhen. Nowadays, Jiangsu, Zhejiang and Shanghai and Guangdong become production bases for foreign ferric oxide manufacturers. Most of these foreign manufacturers mainly purchase primary products of ferric oxide, and then process them, whose annual production capacity exceeds 120,000 ton.

Ferric oxide products are mainly applied in the field of paint, also applied in magnetismmaterials. Ferric oxide is widely applied in paint industry, among inorganic color paints, the output and demand of ferric oxide is the largest. It is applied in various precast concrete units in construction industry and used as paints or colorants for construction products such as color floor tile, metope decoration, terrazzo floor and color tile. In addition, it is also applied in the pigmentation of various paints and protective substances (including water interior & exterior paint, powder paint) and oil paint (including various priming paints and finish paint). Ferric oxide paint can be also applied in rubber, plastic, ceramics, cosmetic, medical, paper and leather industry.

Main Applications of China's Ferric Oxide Products in 2005

Source: China Association of Ferric Oxide Industry

In 2006, the supply of China's ferric oxide will be balanced and ample, not excluding shortage or overstock in some areas or within certain manufacturers at a particular period.

Influenced by the history and social background, China has four major advantages to develop ferric oxide industry: skilled and low-cost labor force, rich raw materials, professional technical personnel and large market at home and abroad.

Ferric oxide industry belongs to a labor-intensive industry with resource and energy consumption. Along with the requirements of China environmental protection policies and development trend, higher requirements are put forward to protect the environment during ferric oxide production. Chinese government attaches great importance to production and management of ferric oxide industry, therefore a reasonable, moderate and feasible control on total demand of ferric oxide has been worked out. China has already released relevant policies to restrict these manufactures in immature production conditions with annual output below 5,000 ton, which not only waste resource but pollute environment, so as to protect exporting manufactures, to ensure reasonably utilize resource and to reduce pollution influences on social environment.

It should also be noted that problems co-exist with the rapid development of China's ferric oxide industry. On one hand, low threshold to ferric oxide industry caused mass production and long-term repeated construction, regardless of market demand; on the other hand, the primary products of China's ferric oxide accounts for a big market share, which means the quality of ferric oxide products is still at middle-low level in international market; moreover, the value added to products is low. Restricted by the requirements of energy, resources and environment, the production of ferric oxide is under higher pressure. Export is also hindered by Euramerican economic fluctuation and trade bulwark.

In general, China's ferric oxide industry has a good prospect. The construction of rural-urban infrastructure will stimulate the demand of ferric oxide as construction paint. Particularly, the start-up of Beijing 2008 Olympics project and Shanghai 2010 World Expo project will drive the development of ferric oxide industry. What's more, the demand of China's ferric oxide products in oversea market is also large. As long as China's ferric oxide manufacturers seize this opportunity, speed up saving energy and reducing energy consumption, develop new products and improve the value added to products, more market shares can be occupied. |

|

|

|

|

2005-2006 www.researchinchina.com All Rights Reserved |

|

| |

|

|

| |

|

1 Overview

1.1 Classification of ferric oxide products

1.2 Application of ferric oxide products2 China's ferric oxide industry and leading suppliers

2.1 China's ferric oxide industry overview

2.2 Shanghai Yipin Pigments Co., Ltd

2.3 Changsha Three-Ring Pigments Development Co., Ltd

2.4 Yixing Yuxing Pigment Factory

2.5 Changshu Ferroxide Factory

2.6 Lanxess Shanghai Pigment Co., Ltd

2.7 Elementis Colours & Chemicals Co., Ltd

2.8 Rockwood

2.9Athay Pigments (China) Co., Ltd

2.10 Zhejiang United Pigment Co., Ltd 3 Status Quo of China's ferric oxide products consumption

3.1Consumption of ferric oxide by industry, 2002-2005

3.2 Proportional distribution of ferric oxide consumption by industry, 2002-2005

3.3 Forecast of ferric oxide use trend by industry

3.4 Ceramics industry

3.4.1 Chaozhou Xuanyu Ceramics Co., Ltd

3.4.2 Chaozhou Fengxi Baodayi Ceramics Co., Ltd

3.4.3 Yixing Zhida Handwork Ceramics Co., Ltd

3.5 Tile industry

3.5.1 Guangdong Dongpeng Ceramic Co., Ltd

3.5.2 Eagle Brand Holdings Limited

3.5.3 Guangdong New Pearl Ceramics Group

3.5.4 Guangdong Monalisa Ceramics (Group) Co., Ltd

3.5.5 ASA Group Holdings Ltd.

3.6 Paint companies

3.6.1 Market analysis of paint industry

3.6.2 Guangdong Hongchang Chemistry Co.,Ltd

3.6.3 Guangdong Huarun Paints Holdings Co., Ltd

3.6.4 Daoqum (Zhongshan) Chemical Enterprise Limited

3.6.5 Hongyun Paint Factory of Guangzhou Zhujiang Chemicals (Group) Co., Ltd

3.6.6 Shenzhen Rainbow Venture Capital Group Co., Ltd

3.7 Plastic industry

3.7.1 Foshan Plastic Group Co., Ltd

3.7.2 Beijing Wanlide Plastic Racetrack Co., Ltd

3.7.3 Jiaxing Buyun Electric Oxygenation Factory

3.7.4 Beijing Shenzhou Sports Facilities Co., Ltd

3.7.5 Nanjing Huati Plastic Co., Ltd 4 Status quo of ferric oxide products import and export

4.1 Overview

4.2 Import analysis

4.3 Export analysis

4.4 Analysis of price trend 5 Status quo of ferric oxide circulation market and leading distributors

5.1 Ferric oxide circulation market overview

5.2 Guangzhou Huasheng Paints & Pigments Co., Ltd 5.3 Guangdong Huayan Chemical Co., Ltd

5.4 Green Chemical Co., Ltd

5.5 Xiamen Continent Trade Co., Ltd

5.6 Beijing H&J Technology Development Co., Ltd

5.7 Chengdu Wanke Manufacture Industry Co., Ltd

5.8 Guangzhou Chutian Color Chemical Co., Ltd

5.9 Shanghai Xiangqi Industry& Trade Co., Ltd

5.10 Beijing Kangzhiwei Technology & Trade Co., Ltd

(Beijing Kangyuan United Pigments Company)

5.11 Other distributors 6 Opportunities and risks of ferric oxide industry

6.1 Opportunities

6.2 Risks

6.3 Competition strategies

|

|

|

|

|

2005-2006 www.researchinchina.com All Rights Reserved |

|

| |

|

|

| |

|

Main applications of China's ferric oxide products in 2005

Output of China's ferric oxide by variety, 2001-2005

Global sales network of Yipin

Sales flow of Yuxing's ferric oxide products

Sales network of Athay's ferric oxide pigments

Status quo of Changshu Ferroide Factory's sales circulation

Organization structure of ASA

Overview of major manufactures' marketing modes and distributors in China

Overview of Huasheng's agent pigments from Lanxess

Overview of Huayan's partial agent ferric oxide products from Lanxess

Status quo of Huayan's sales and management

Overview of Continent's agent brands

Overview of Yipin pigments sales network in China

Overview of Xiangqi's consigned products

Status quo of Athay's sales and management by branch

Status quo of ferric oxide use by industry, 2002-2005

Proportional distribution of ferric oxide consumption by industry, 2002-2005

Forecast of ferric oxide use trend by industry, 2006-2010

Status quo of economic indicators of ferric oxide industry, 2002-2005

Sales of leading enterprises in ferric oxide industry, 2005

Sales of leading enterprises in ferric oxide industry, 2004

Factory price and distributor price of Yinpin pigments

Ferric oxide output of Yipin, 2004-2005

Ferric oxide sales volume of Yipin, 2004-2005

Ferric oxide sales status of Yipin, 2004-2005

Factory price and distributor price of Three-Ring's ferric oxide products

Ferric oxide output of Three-Ring, 2004-2005

Ferric oxide sales volume of Three-Ring, 2004-2005

Ferric oxide sales of Three-Ring, 2001-2005

Factory price of Yuxing's ferric oxide products

Ferric oxide output of Three-Ring 2004-2005

Ferric oxide sales volume of Three-Ring 2004-2005

Ferric oxide sales of Three-Ring 2004-2005

Ferric oxide output of Changshu Ferroxide Factory, 2004-2005

Ferric oxide sales volume of Changshu Ferroxide Factory, 2004-2005

Ferric oxide sales of Changshu Ferroxide Factory, 2004-2005

Factory price and distributor price of Lanxess's ferric oxide products

Ferric oxide output of Lanxess, 2004-2005

Lanxess's purchase volume of ferric oxide in China, 2004-2005

Ferric oxide sales of Lanxess, 2004-2005

Ferric oxide sales of Elementis, 2004-2005

Elementis's purchase volume of ferric oxide, 2004-2005

Ferric oxide sales of Elementis, 2004-2005

Rockwood's output of ferric oxide in China, 2004-2005

Rockwood's purchase volume of ferric oxide, 2004-2005

Sales of Rockwood in China, 2004-2005

Ferric oxide output of Athay in China, 2004-2005

Athay's purchase volume of ferric oxide in China, 2004-2005

Sales of Athay in China, 2004-2005

Distributor price of United Pigment

Ferric oxide output of United Pigment, 2004-2005

Ferric oxide sales volume of United Pigment, 2004-2005

China's ferric oxide products export, 2001-2005

Destination countries' purchase volume and purchasing price of exported ferric oxide

Destination areas' purchase volume and purchasing price of exported ferric oxide

Status quo of ferric oxide export by province and city

Import and export of China's ferric oxide products, 2001-2005

Status quo of ferric oxide import and export by province and city

|

2005-2008 www.researchinchina.com All Rights Reserved

|