China Automotive Integrated Die Casting Industry Research Report, 2022

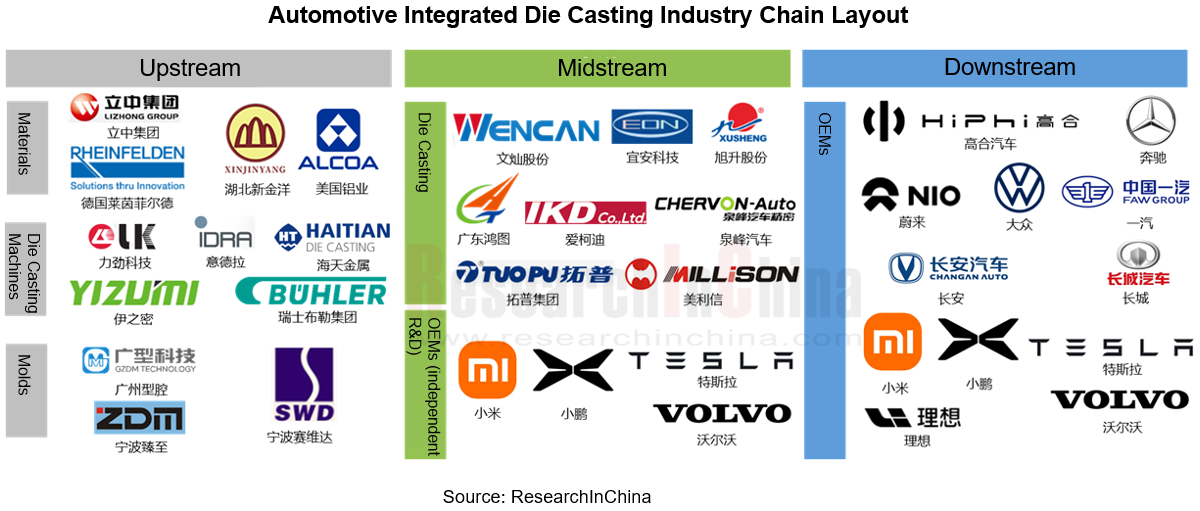

Integrated Die Casting Research: Upstream, midstream and downstream companies are making plans and layouts in this booming field

Automotive integrated die casting is an automotive manufacturing process proposed and put into practice by Tesla. It redesigns and highly integrates multiple separate and scattered small parts in the original design, then uses a large die casting machine to perform high-pressure die casting at one time, and directly produces a complete large part without the welding process. Compared with traditional automotive manufacturing, automotive integrated die casting has advantages in manufacturing cost, production efficiency, labor cost, model development cycle, performance, materials recycling, etc.

Against the traditional concept that product and process design hinges on the existing conditions and capabilities, Tesla prefers reverse thinking. Taking automotive integrated die-casting as an example, Tesla determines how large the part can be to achieve the best effect, then deduces how much equipment, tooling and materials are needed. Afterwards, it cooperates with suppliers to develop new equipment, corresponding molds, materials and new processes. This kind of thinking has greatly inspired the innovation of the traditional industry and brought upheaval and the secondary innovation to the industry.

OEMs master the know-how of integrated die casting through independent research and development

After Tesla Model Y adopted the integrated die casting process for the first time, a new wave of integrated die casting has staged worldwide. A complete industrial chain layout has been formed between upstream die casting machine manufacturers, material manufacturers and mold manufacturers, as well as midstream die-casting companies and downstream automakers.

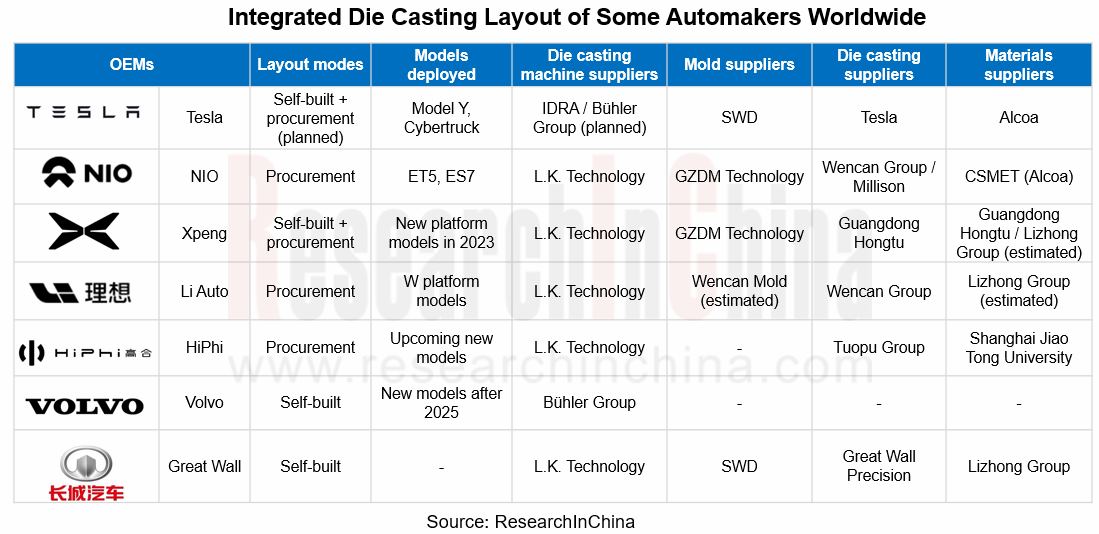

There are currently two main business modes:

Independent research and development of OEMs: OEMs: directly purchase die casting machines, molds and materials, and then build their own factories to produce die casting parts. Tesla, Xpeng and Volvo adopt this mode.

Independent research and development of OEMs: OEMs: directly purchase die casting machines, molds and materials, and then build their own factories to produce die casting parts. Tesla, Xpeng and Volvo adopt this mode.

Procurement: OEMs directly purchase die casting parts from die-casting manufacturers who buy relevant materials to produce die casting parts and deliver them to OEMs. HiPhi, NIO and Li Auto follow this mode.

Procurement: OEMs directly purchase die casting parts from die-casting manufacturers who buy relevant materials to produce die casting parts and deliver them to OEMs. HiPhi, NIO and Li Auto follow this mode.

In the long run, automotive integrated die casting will gradually return to the procurement mode. OEMs have to invest heavily in building their own production lines, and they may be extremely concerned about the later operation and management. Tesla, the representative of the independent R&D mode, has cooperated with die casting manufacturers in order to add new capacity by outsourcing in the future. The main purpose of the OEM's self-research is to master the know-how of integrated die-casting, which is convenient for technical communication with suppliers in the future.

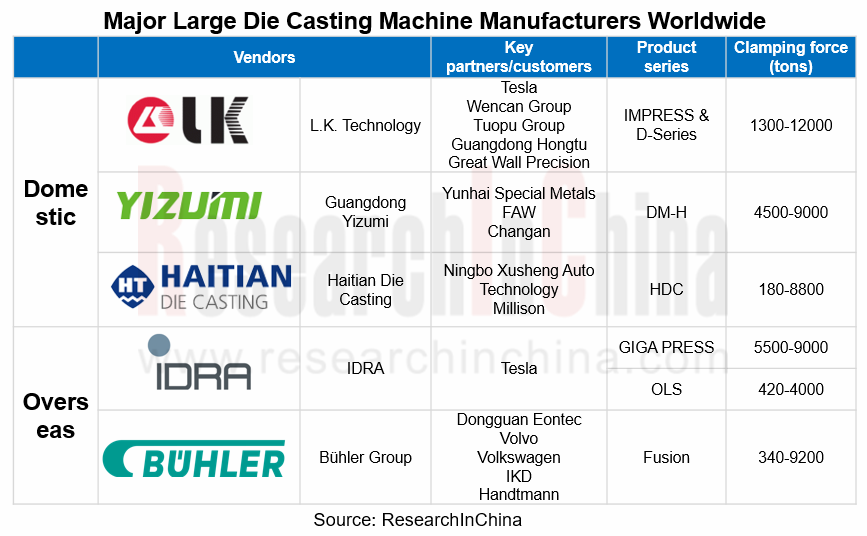

Upstream: Super-large die casting machines debuted, helping vehicle-level integrated die casting

Large die casting machines are the key to realizing automotive integrated die casting. At present, integrated die casting requires 6000T (or above) die casting machines. Globally, IDRA (a wholly-owned subsidiary of L.K. Technology), Bühler Group, as well as China-based L.K. Technology, Haitian Die Casting and Guangdong Yizumi can produce die casting machines over 6000T.

Higher-tonnage die casting machines can facilitate breakthroughs in die casting size and structure. Now, Tesla, L.K. Technology, Guangdong Hongtu, Haitian Die Casting and other companies have started research and development of die casting machines above 12,000T. In September 2022, L.K. Technology and Guangdong Hongtu successfully released a 12,000T super-large intelligent die casting unit jointly, marking the advent of world's highest-tonnage die casting machine. This is expected to boost vehicle-level integrated die-casting.

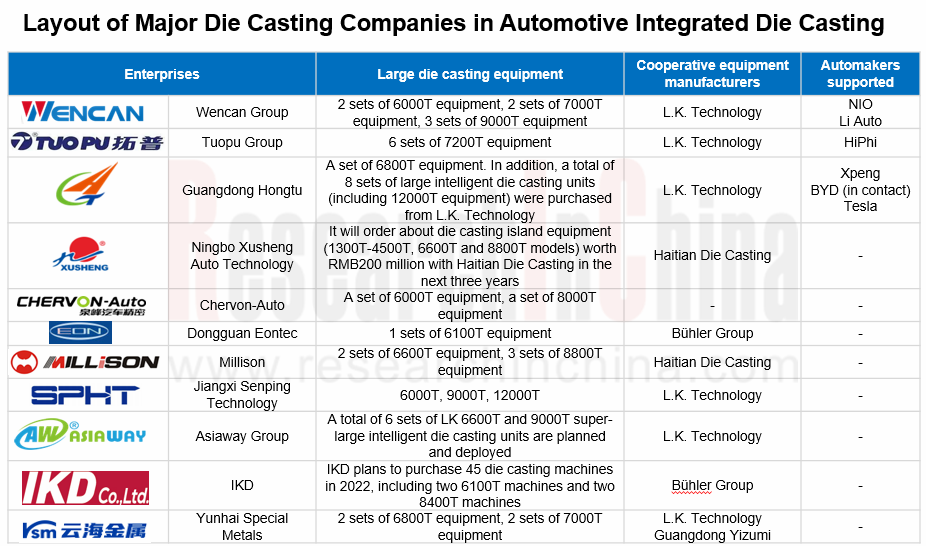

Midstream: Die casting leaders emerged

As midstream die-casting companies, Wencan Group, Tuopu Group, Guangdong Hongtu, Xusheng Auto Technology, Millison, etc., have deployed automotive integrated die casting by purchasing large die casting equipment and cooperating with automakers.

Currently, Wencan Group, Tuopu Group and Guangdong Hongtu have first-mover advantages in experience accumulation and order intake. All three have established cooperation with automakers and successfully completed the trial production of integrated die casting parts. Especially, Guangdong Hongtu is superior to others thanks to its heat-treatment-free aluminum alloy patent and the yield rate of 85%-90%. So far, it has not only obtained the designation from Xpeng, but also become Tesla's only die casting partner in integrated die casting.

Downstream: Automakers scramble to deploy integrated die casting in a bid to integrate the upper and lower car body

At present, Tesla, NIO, Xpeng, HiPhi, Volvo, Great Wall and other automakers have made layout in the field of automotive integrated die casting.

In terms of emerging automakers, Tesla has officially delivered Model Y with integrated die casting floors. NIO ET5 with an integrated die casting rear subframe is about to be delivered. In addition, Xpeng, Li Auto and HiPhi have put integrated die casting on the agenda, and they may apply it to vehicles in 2023.

In terms of emerging automakers, Tesla has officially delivered Model Y with integrated die casting floors. NIO ET5 with an integrated die casting rear subframe is about to be delivered. In addition, Xpeng, Li Auto and HiPhi have put integrated die casting on the agenda, and they may apply it to vehicles in 2023.

As for traditional automakers, Volkswagen and Volvo have a long-term timetable for the layout of integrated die casting, and they expect to achieve mass production around 2025. Chinese automakers Changan and Great Wall have started bidding for integrated die casting projects, and they are likely to accomplish mass production in the next two to three years.

As for traditional automakers, Volkswagen and Volvo have a long-term timetable for the layout of integrated die casting, and they expect to achieve mass production around 2025. Chinese automakers Changan and Great Wall have started bidding for integrated die casting projects, and they are likely to accomplish mass production in the next two to three years.

Now, major OEMs mainly apply integrated die casting to the rear floor, the front cockpit, etc. With the advent of higher-tonnage die casting machines, integrated die casting is expected to spread to lower body assembly, upper body integrated casting parts, and even body-in-white in the future.

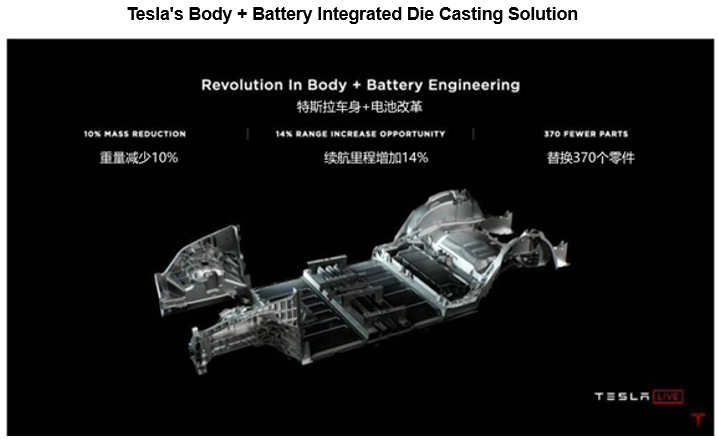

Tesla plans to replace the 370-part lower body assembly with 2-3 large die casting parts. Tesla has extended the integrated die casting to the front and rear floors. At the same time, the upper cover of the battery pack and the middle floor of the vehicle are combined into one for integrated die casting, which can reduce the vehicle weight by 10% and increase the cruising range by 14%.

In addition, Wencan Group has successfully trial-manufactured large integrated casting parts on the upper body, and it will deliver samples in small batches later.

Automotive AI Algorithm and Foundation Model Application Research Report, 2023

Large AI model research: NOA and foundation model facilitate a disruption in the ADAS industry.

Recently some events upset OEMs and small- and medium-sized ADAS companies, as the autonomous driving i...

Intelligent Cockpit Domain Controller and SoC Market Analysis Report, 2023Q2

Cockpit domain controller and chip in 2023Q2: by intelligent cockpit level, L1 surged by 105% on a like-on-like basis, and L2 soared by 171%.On May 17, 2023, the “White Paper on Automotive Intelligent...

Intelligent Vehicle E/E Architecture Research Report, 2023

E/E Architecture Research: How will the zonal EEA evolve and materialize from the perspective of supply chain deployment?Through the lens of development trends, automotive EEA (Electronic/electrical A...

China Passenger Car Brake-by-wire Industry Report, 2023

Passenger car brake-by-wire research: One-box solution takes an over 50% share.

China Passenger Car Brake-by-wire Industry Report, 2023 released by ResearchInChina combs through and summarizes passe...

Smart Car OTA Industry Report, 2023

Vehicle OTA Research: OTA functions tend to cover a full life cycle and feature SOA and central supercomputing.In the trend for software-defined vehicles, OTA installations are surging, and software i...

Intelligent Vehicle Multi-Domain Computing Industry Report, 2023

Multi-domain computing research: in the coming first year of cross-domain fusion, major suppliers will quicken their pace of launching new solutions.

As vehicle intelligence develops, electrical/ele...

Automotive Head-up Display (HUD) Industry Report, 2023

Automotive HUD research: in the "technology battle" in AR-HUD, who will be the champion of mass production?

Automotive head-up display (HUD) works on the optical principle for real-time display of s...

Automotive Cloud Service Platform Industry Report, 2023

Research on Automotive Cloud Services: As Dedicated Automotive Cloud Platforms Are Launched, the Market Enters A Phase of Differentiated Competition

1. The exponentially increasing amount of v...

Global and China Automotive Gateway Industry Report, 2023

Automotive gateway research: integrated gateways have become an important trend in zonal architecture.

Automotive gateway is a core component in the automotive electronic/electrical architecture. As ...

In-vehicle Communication and Network Interface Chip Industry Report, 2023

In-vehicle communication chip research: automotive Ethernet is evolving towards high bandwidth and multiple ports, and the related chip market is growing rapidly.

By communication connection form, au...

China Autonomous Driving Data Closed Loop Research Report, 2023

Data closed loop research: in the stage of Autonomous Driving 3.0, work hard on end-to-end development to control data.

At present, autonomous driving has entered the stage 3.0. Differing from the s...

ADAS and Autonomous Driving Tier 1 Research Report, 2023 - Foreign Companies

Research on foreign ADAS Tier 1 suppliers: 4D radar starts volume production, and CMS becomes a new battlefield.

1. Global Tier 1 suppliers boast complete ADAS/AD product matrix, and make continuous...

China Passenger Car Driving-parking Integrated Solution Industry Report, 2023

Research on driving-parking integration: with the declining share of the self-development model, suppliers' solutions blossom.

Local suppliers lead the driving-parking integration market.

The statis...

Passenger Car Cockpit Entertainment Research Report, 2023

Cockpit entertainment research: vehicle games will be the next hotspot.

The Passenger Car Cockpit Entertainment Research Report, 2023 released by ResearchInChina combs through the cockpit entertainme...

Smart Road - Roadside Perception Industry Report, 2023

Roadside perception research: evolution to integration, high performance and cost control.In June 2023, at a regular policy briefing of the State Council the Ministry of Industry and Information Techn...

China Passenger Car ADAS Domain Controller,Master Chip Market Data and Supplier Research Report, 2023Q1

Quarterly Report on ADAS Domain Controllers: L2+ and above ADAS Domain Controller Master Chip Market Structure This report highlights the passenger car L2+ and above (including L2+, ...

Automotive Cockpit Domain Controller Research Report, 2023

Research on cockpit domain controllers: various forms of products are mass-produced and mounted on vehicles, and product iteration speeds up.

Both quality and quantity have been improved, and the it...

Chinese Passenger Car OEMs’ Overseas Layout Research Report, 2023

OEMs’ overseas layout research: automobile exports are expected to hit 7.18 million units in 2025.

1. China’s automobile export market bucked the trend.

During 2021-2022, the global economy ...